ANRO

Impact Compaction

Manufacturers of Compaction Equipment

Who Are We and What Do We Do?

ANRO IMPACT COMPACTION (Pty) Ltd specializes in the manufacture of impact compactors.

The company has pioneered the development of the impact compactor and manufactures high energy impact compactors for the construction industry.

As a world leader in impact compaction we offer you a complete compaction solution. With over 30 years experience Roger Stromsoe has the knowledge, expertise and skills to provide you with compaction equipment that is unrivalled in the construction industry.

As ground improvement specialists, the company has also provided impact compactors to the construction industry on a contract or hire basis.

The superior compaction capability of our 3 and 5 sided impact compactors will cut your compaction costs and contract programme time. Our state of the art impact compactors are all built to the highest specifications and quality, ensuring maximum availability on your site.

Cost conscious contractors and consulting engineers use our impact compactors to achieve:

-

Deep in situ compaction

-

Thick layer compaction

-

Lower cost per cubic meter

-

Higher compaction speeds

-

Effective proof rolling

-

Increased bearing capacity

-

Greater quality assurance

We supply the best compaction equipment that the industry has to offer. Our commitment to service excellence ensures that the compaction specifications on your contract are always successfully achieved.

What Is Compaction

Traditional approaches to compaction have centered on compaction plant which has relied on static weight, kneading action or vibratory rolling of the soil to achieve the desired improvement in strength and bearing capacity. However, the demand for more efficient, economic and reliable compaction has led to the development of a radically new type of compaction plant, the non-circular impact compactor.

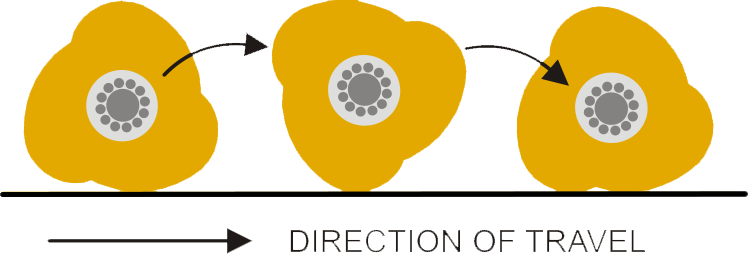

The impact compactor is a mobile dynamic compactor and the design is based on the simple principle whereby compaction effort is derived from the energy of the drum falling from a corner to a flat as the shaped drum is towed along the ground. Because of the high energy delivered by each blow, the impact compactor is capable of producing effective compaction in thicknesses considerably greater than previously possible.

The distinguishing feature of all impact compactors is their non-circular compacting drums which have a series of points alternating with flat compacting faces. Impact compactors vary in relation to shape (3 or 5 sided) mass and energy rating. During the compaction process, the impact compactor drums are towed along the ground by a wheeled tractor at a relatively high speed of 10 to 12 km/h, compared to typical conventional roller speeds of 2 to 3 km/h. This operation causes the drums to rotate by contact with the ground and to alternatively rise up on their points and then fall downward onto their compacting faces. This action produces a series of high impact, high amplitude blows.

In order for compaction equipment to achieve the maximum effectiveness in respect of density and depth of soil compaction, the following principles apply:

-

The compaction force needs to be applied over a large area.

-

The force needs to be dynamic and applied with high amplitude and low frequency.

-

The “parcel of energy” which produces the compacting force needs to be large.

-

All these principles are embodied in the design of the impact compactor.

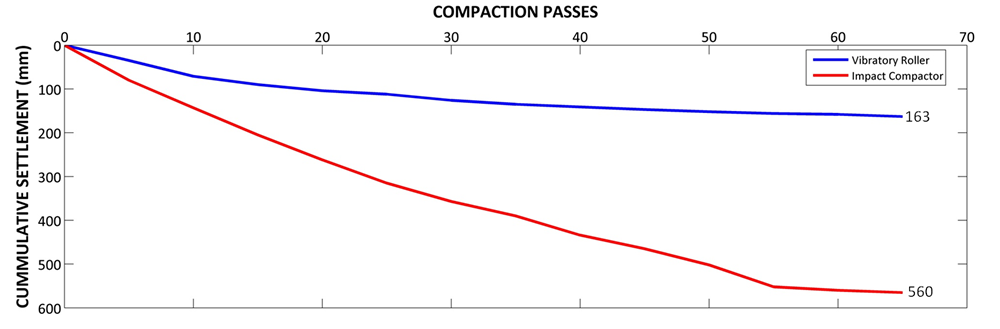

The following graph compares the amount of settlement achieved with an impact compactor and a heavy vibro roller on a construction site consisting of collapsing sand. The extent to which one can achieve settlement of the ground surface determines the extent to which one can improve the soil strength and increase the bearing capacity.