Our Products

Anro Impact Compaction manufactures two types of impact compactors – 5 sided and 3 sided compactors. The compactors are rated according to their energy output, the 5 sided being a 15kJ compactor and the 3 sided a 30kJ compactor.

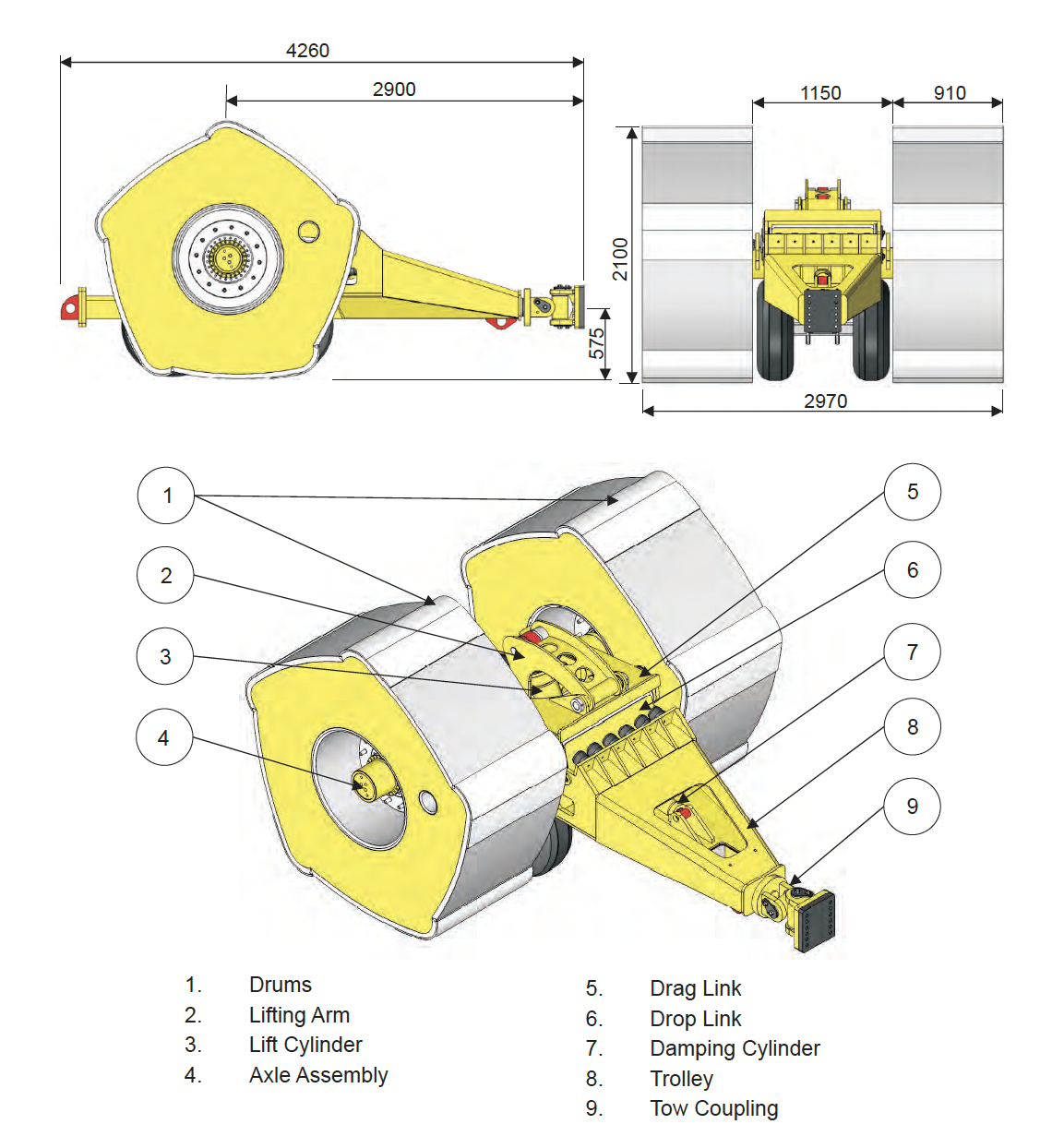

The 5 sided impact compactor is a more general purpose compactor and iS mainly used on earthworks where use of this impact compactor makes it possible to place material in thick layers. Depending on the material type, fill can be placed in layers 500mm to 700mm thick and more. This gives the 5-sided compactor an output of about 2000 m’ per hour compared to the output of a vibro roller of about 300 mi per hour on the same material.

The 5-sided compactor is also used on in situ material on sites where only moderately deep compaction is required.

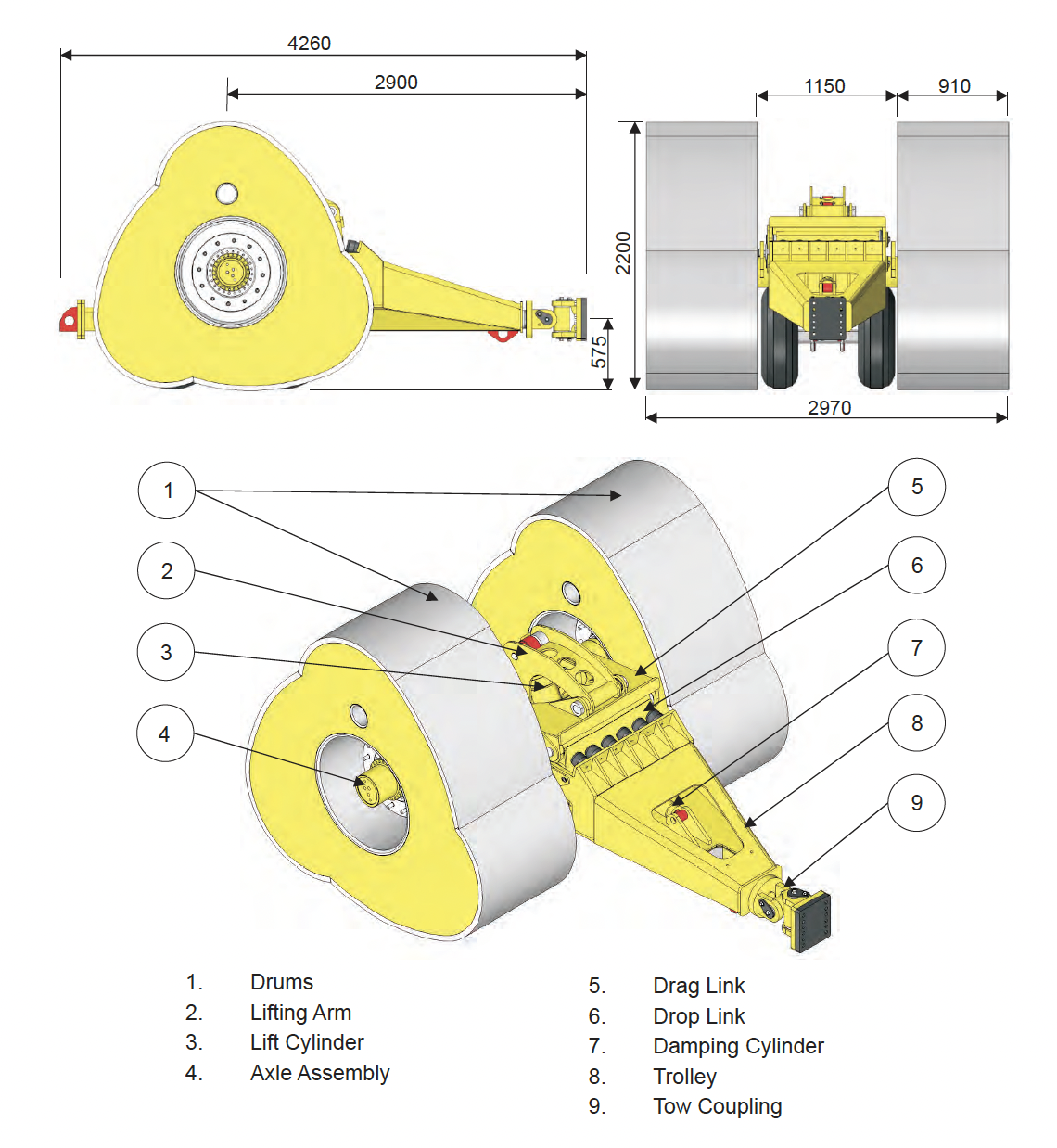

The 30 kJ, 3-sided impact compactor is generally used for the compaction of in situ material on sites where deep compaction is required. Because the depth of influence of an impact compactor is significantly greater than that of conventional equipment, use of the 3-sided compactor usually makes it possible to satisfactorily compact soil from the surface instead of having to remove the soil and replace it in layers as would be the case with vibro rollers. Depending on the material type, in situ material can be improved to depths of up to 3 meters. On many construction sites the impact compactor has been the only compactor that could achieve the required densities by compacting the site surface without having to remove and replace the material in layers, resulting in a large a cost saving. The 3-sided compactor is also used on fill where there S an advantage in placing very thick layers.

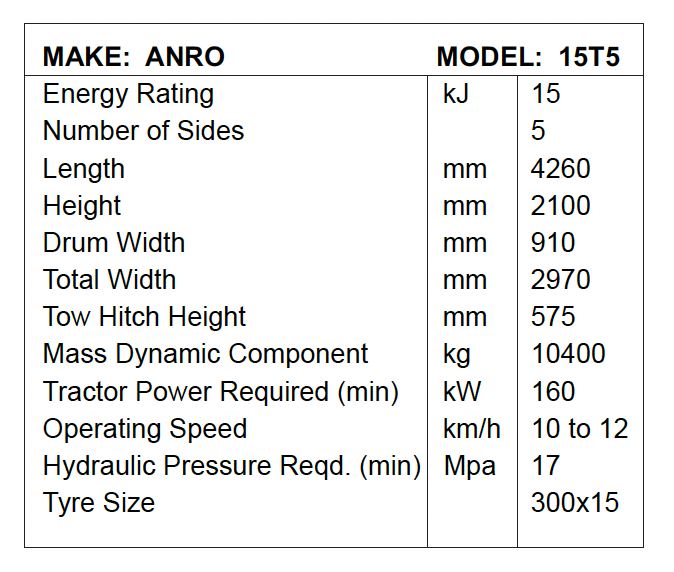

15 kJ, 5 sided Impact Compactor

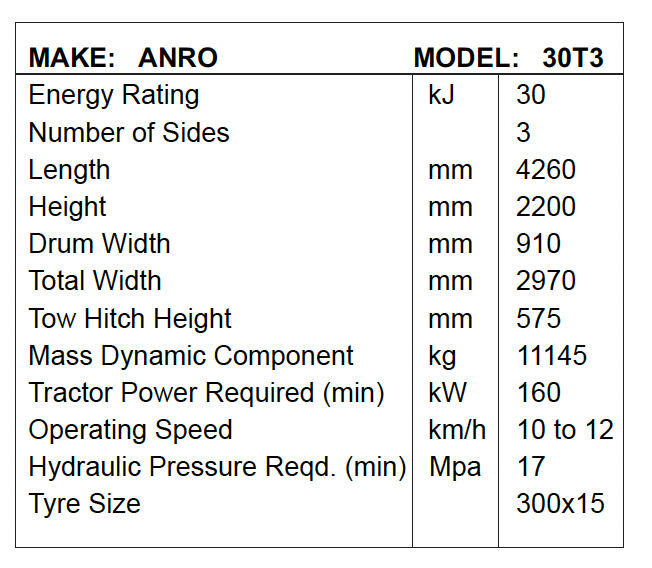

30 kJ, 3 sided Impact Compactor